Home > Technical Support > Molding Technology > Molding Technology for TOPAS(R) COC

Mold design

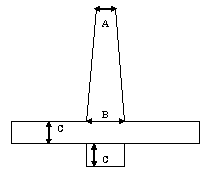

7. Mold design 7.1 Sprues, runners (1) Cold runners (a) Runners In consideration of pressure loss, we generally recommend runners that are circular in cross section, and secondly, trapezoidal runners. However, since TOPAS® COC has good mold transferability, the irregularities on the surfaces right-angled to the parting surfaces of a circular runner may become undercuts, and poor mold release or chipping may occur as a result. Fig. 7-1 shows an example of a circular runner for TOPAS, in which such trouble can be prevented by deforming a true circle so that the surfaces right-angled to the parting surfaces are minimized as can be seen.

(b) Runner size From the aspects of suppression of cooling of molten resin and reduction of pressure loss, it is better if runners are thicker, but it is also necessary to make decisions regarding runner size taking into consideration economic aspects such as reducing runner ratio.

Fig. 7-1 Examples of runner design

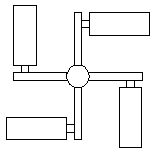

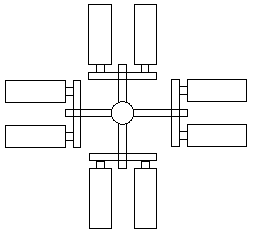

(c) Sprue and runner arrangement Basically, a multiple-cavity mold should be designed so that respective cavities are filled with resin simultaneously as the runner lengths and thicknesses are identical and are also arranged symmetrically. What is especially important is a cold slug well, which should always be provided at the intersection of each runner. Fig. 7-2 shows an example of sprue and runner design, and Fig. 7-3 shows examples of runner arrangement and design.

Fig. 7-2 Example of sprue and runner design for TOPAS® COC

Fig. 7-3 Examples of runner arrangement and design for a 4-cavity mold and 8-cavity mold

(2) Hot runners Hot runners can also be used for transparent materials, but it should be kept in mind that resin damage by in-hot-runner heating is greater than that by in-cylinder heating. Therefore, it is not recommended for optically rigorous items because trouble resulting from mixing of carbides, discoloration, etc., is probable. In order to prevent such trouble, it is necessary to select hot runners designed to be suitable for optical materials and follow appropriate directions for use. Hot runners suitable for transparent resins are to be designed with no dead space (resin residence) in consideration of internal polish, material, etc. For details, contact us.

|