Home > Technical Support > Molding Technology > Molding Technology for DURACON(R) POM

Mold Design / Gates

8. Mold Design 8.2 Gates Gate Size:

However, if no quality problems result, a smaller sized gate can be used to improve molding cycle, automation of gate finishing work, etc.

Gate Position:

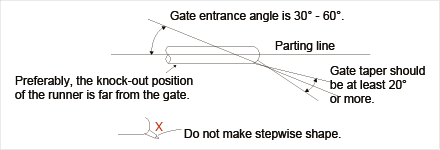

Gate Structure: Since DURACON® POM does not require a special gate shape, a common gate shape can be used. However, when a pin gate or tunnel gate is employed, improper degating may occur in some shapes. Notes are shown in Fig. 8-4.

|