Home > Technical Support > Molding Technology > Molding Technology for DURACON(R) POM

Molding Conditions / Predrying

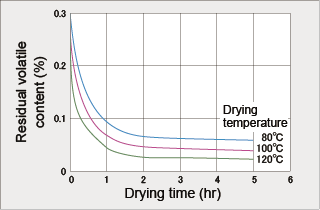

4. Molding Conditions 4.2 Predrying Though DURACON® POM has a substantially low moisture absorption rate and the packaging bags are completely sealed, it is recommended to predry pellets before use. The allowable level for moisture absorption of molding pellets is usually 0.1% or less. Predrying conditions

Notes

Fig. 4-1 Pellet drying curve

|