Home > Technical Support > Molding Technology > Molding Technology for DURACON(R) POM

Molding Characteristics / Mold Shrinkage

6. Molding Characteristics

6.2 Mold Shrinkage

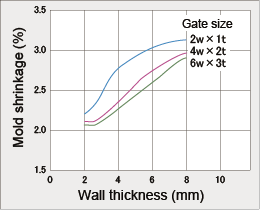

Fig. 6-5 Mold shrinkage of M90-44 (side gate) |

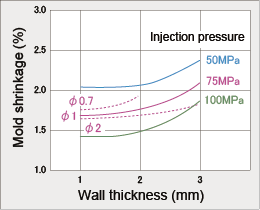

Fig. 6-6 Mold shrinkage of M90-44 (pin gate) |

Molding conditions:

Injection pressure: 50MPa

Cylinder temp.: 190°C

Mold temp.: 80°C

Injection speed: 50mm/s

Mold: 80×80mm flat plate |

Molding conditions:

Cylinder temp.: 190°C

Mold temp.: 80°C

Injection speed: 17mm/s

Mold: 50×50mm flat plate

Pin gate: 1.0mm dia. |

Table 6-1 Relation of molding conditions and mold shrinkage

| |

Change |

Mold shrinkage |

After-shrinkage |

| Walk thickness |

↑ Thick |

↑ Large |

↓ Small |

| Gate size |

↑ Large |

↓ Small |

|

| Mold temperature |

↑ High |

↑ Large |

↓ Small |

| Material temperature |

↑ High |

↑ Large |

|

| Holding pressure |

↑ High |

↓ Small |

|

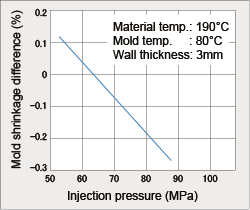

Fig. 6-7 Relationship between injection

pressure and mold shrinkage |

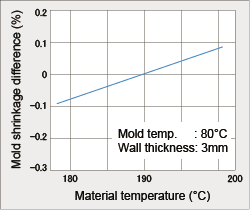

Fig. 6-8 Relationship between material

temperature and mold shrinkage |

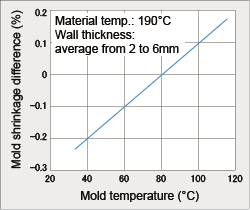

Fig. 6-9 Relationship between mold

temperature and mold shrinkage |

|

|