Home > Technical Support > Molding Technology > Molding Technology for TOPAS(R) COC

Molding conditions

4. Molding conditions

4.9 Measures against stringiness

The viscosity of TOPAS® COC is controlled low in order to improve its moldability. As a result, problems such as stringiness and drooling may occur. In such cases, first take the following measures.

- Take a suck-back. Note that taking it too much will result in entry of bubbles. Basically, set to approximately 1/10 of the screw diameter.

- Perform sucking back immediately before the mold opens. Set by metering delay or suck-back delay.

- Decrease nozzle temperature. As a guide, decrease in steps of 5 degrees. Note that decreasing it too much will result in solidification at nozzle tip and unstable injection.

- There are cases where stringiness is difficult to stop depending on the shape or type of the nozzle of the molding machine; e.g., nozzle diameter is large or nozzle tip design is not suitable for low-viscosity resins. Contact us if stringiness cannot be stopped by taking the above measures because measures to be taken differ with situations.

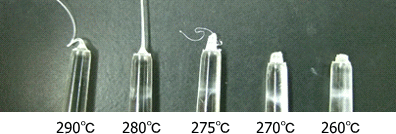

Fig. 4-5 shows nozzle tip temperatures and stringing conditions. (Molding machine = Sumitomo SE75D, Mold temperature = 110°C) From this, it can be seen that stringiness can be corrected by decreasing the nozzle tip temperature.

Fig. 4-5 Nozzle tip temperatures and stringing conditions

|