Home > Technical Support > Molding Technology > Molding Technology for TOPAS(R) COC

Molding conditions

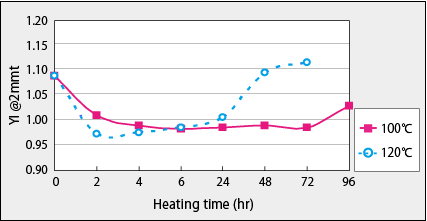

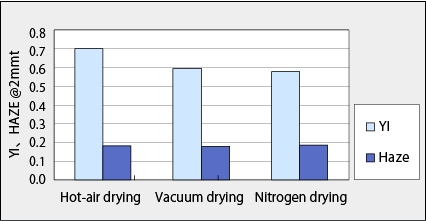

4. Molding conditions 4.2 Pre-drying Although TOPAS® COC does not absorb moisture, pre-drying is required to deoxidize the pellets. General hot-air drying is acceptable. For the 5013 family, 6013 family, 6015 family, and 6017 family, perform pre-drying at 100°C for 6 hours. For 8007, which does not usually need drying, perform pre-drying at 60°C for 24 hours if stringent optical characteristics are required. Fig. 4-1 shows drying conditions and YI changes of TOPAS 6013S-04. In drying at 120°C, oxidization of pellets proceeds due to extra drying of several hours and YI goes up. In drying at the recommended 100°C, YI never goes up over an extended period of time. With a hopper dryer or the like that will have problems in pellet replacement, 100°C drying should be performed in a range of 6 hours to 24 hours. Although dehumidification drying is not needed, vacuum drying or drying by nitrogen replacement is recommended for products with stringent color tone and yield requirements. Fig. 4-2 shows the relationship between YI, Haze and drying conditions of TOPAS 5013L-10. It can be seen that vacuum drying and drying by nitrogen replacement show lower YI and better optical characteristics.

Fig. 4-1 Relationship between drying temperature and YI of TOPAS® 6013S-04

Fig. 4-2 Effects on YI and Haze according to drying conditions of TOPAS® 5013L-10

|