Home > Technical Support > Molding Technology > Molding Technology for DURAFIDE(R) PPS

3. Use of Regrinds

Use of regrind is possible; however, molding material of 100% regrind will have mechanical and thermal properties slightly degraded by the breakage of glass fibers and, moreover, change in hue may occur. When using a recycled material, it is recommended to use a material which is blended regrind in a constant ratio below 25%. Table 3-1 shows property retention of 1140A1 when mixed with a recycled material, and Table 3-2 shows property retention of 1140A1 when the whole amount is used for three times repeatedly.

Under UL standards, use of up to 25% regrinds is approved. Further, in some grades, use of up to 50% regrind is possible. For details, please refer to Yellow Card (File no. E109088). |

|

Table 3-1 Property Retention of DURAFIDE® 1140A1 When Mixed

with Regrind |

Item |

Property retention (%) |

Content of regrind (%) |

0 |

30 |

50 |

70 |

100 |

| Tensile strength |

100 |

99 |

98 |

97 |

96 |

| Elongation |

100 |

103 |

102 |

102 |

104 |

| Flexural strength |

100 |

99 |

97 |

98 |

97 |

| Flexural modulus |

100 |

102 |

100 |

99 |

100 |

| Izod impact strength |

Notched |

100 |

103 |

97 |

99 |

90 |

| Unnotched |

100 |

99 |

100 |

95 |

97 |

| Change in hue (ΔE) * |

- |

2.2 |

3.0 |

3.5 |

5.0 |

|

| |

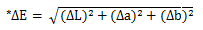

*  |

| |

Change in hue is shown by the value of Δ instead of retention rate. |

|

Table 3-2 Property Retention of DURAFIDE® 1140A1 after Recycling

Whole Amount Three Times |

|

Item |

Property Retention (%) |

Granulated |

Reclaimed pellet |

| Tensile strength |

82 |

78 |

| Tensile elongation |

100 |

97 |

| Tensile modulus |

90 |

- |

| Flexural strength |

87 |

85 |

| Flexural modulus |

94 |

89 |

| Izod impact strength |

Notched |

72 |

51 |

| Unnotched |

84 |

75 |

| Heat distortion temperature under load * |

97 |

97 |

| Change in hue (ΔE) ** |

13.8 |

- |

| Melt index |

- |

220 |

| Shrinkage (Flow dir.) |

- |

135 |

|

| |

* 1.82MPa |

| |

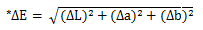

**  |

| |

Change in hue is shown by the value of ΔE instead of retention rate. |

|