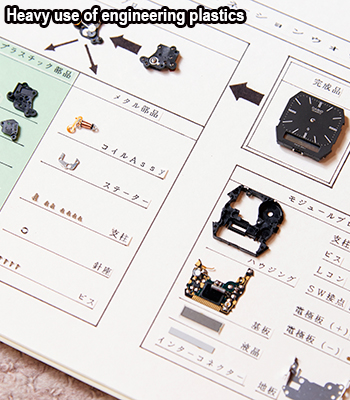

In the past, module components of watches were made of metal. Substituting engineering plastics for metal facilitated production makes possible flexible adaptability to design modifications, weight reduction, and low cost.

Precision parts made of compounded resins to prevent shape change, cracking, and other damage and cast in precision molds to satisfy the requirements of wear resistance, sliding ability, thermostability, and a certain degree of lubricating ability, enabled high quality at low cost.