Home > Technical Support > Molding Technology > Molding Technology for TOPAS(R) COC

Product design

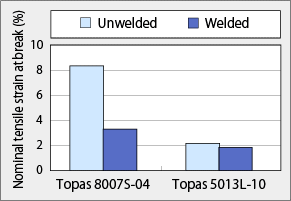

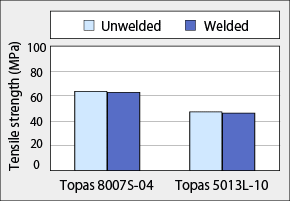

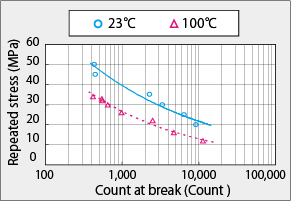

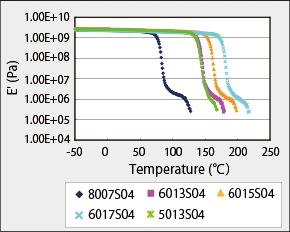

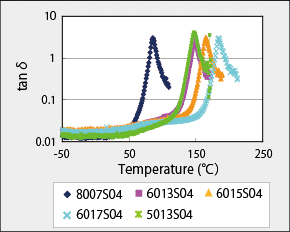

6. Product design 6.5 Other properties Figs. 6-12 and 6-13 show weld strength. While strength is not greatly affected, elongation decreases due to the effect of notching. Table 6-2 shows pencil hardness. Fig. 6-14 shows fatigue characteristics. Fig. 6-15 shows dynamic solid viscoelasticity. In addition, values of Poisson ratio, etc., are shown.

Table 6-2 Pencil hardness

Fig. 6-15 Dynamic solid viscoelasticity of TOPAS® COC (measuring frequency: 10 Hz)

Other data: Poisson ratio:

SP value: 7.8 (cal/cm³)1/2,A16 (MPa)1/2

|