Home > Technical Support > Molding Technology > Molding Technology for TOPAS(R) COC

Molding characteristics

5. Molding characteristics

5.3 After-shrinkage

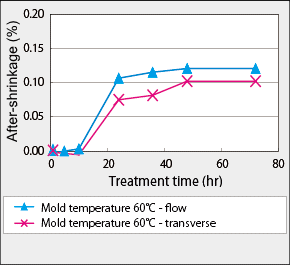

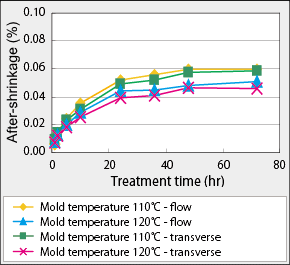

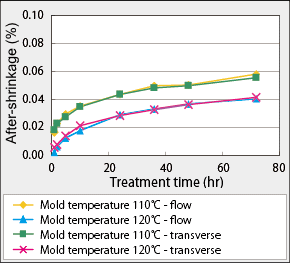

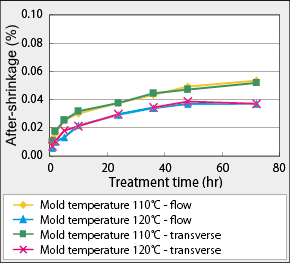

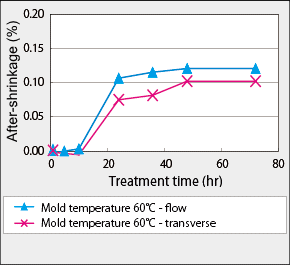

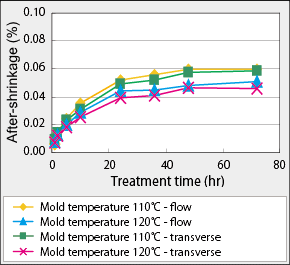

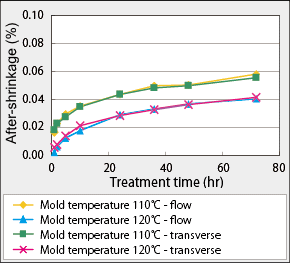

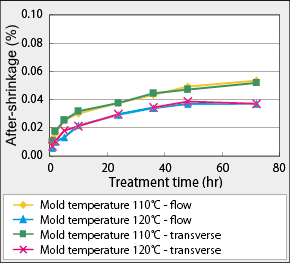

Fig. 5-10, Fig. 5-11, Fig. 5-12 and Fig. 5-13 show after-shrinkage by annealing of 8007S-04, 5013L-10, 6013S-04, and 6015S-04, respectively. Rresins shrink due to annealing, by which molding distortion is relieved. Basically, we recommend that the annealing temperature is lower than mold temperature and 20°C lower than DTUL.

Fig. 5-10 After-shrinkage of 8007S-04

(50°C annealing, 2 mm thickness) |

Fig. 5-11 After-shrinkage of 5013L-10

(100°C annealing, 2 mm thickness) |

Fig. 5-12 After-shrinkage of 6013S-04

(100°C annealing, 2 mm thickness) |

Fig. 5-13 After-shrinkage of 6015S-04

(120°C annealing, 2 mm thickness) |

|