Home > Technical Support > Molding Technology > Molding Technology for DURANEX(R) PBT

After-shrinkage

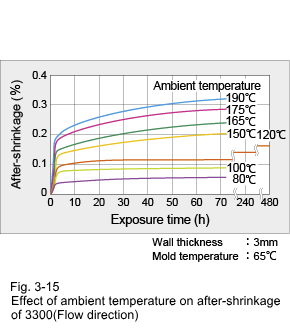

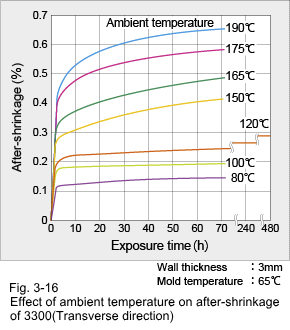

3.2 Shrinkage (2) After-shrinkage The dimensions of molded products change depending on the conditions under which they are used. This is caused by relaxation of molded-in stress, progress of crystallization, moisture or water absorption and thermal expansion. Therefore, it is sometimes necessary to take measures to stabilize the dimensions of molded parts in advance of use, taking these conditions into consideration. The effects of annealing temperatures on such after-shrinkage are shown in Figs. 3-15 and 16, which indicate that the higher the annealing temperature, the more the after-shrinkage is and that after-shrinkage is greater in the transverse direction than in the flow direction. Whether or not annealing is necessary to stabilize the dimensions of a part depends on the conditions under which it is to be used. Estimates based on the after-shrinkage data (Figs. 3-15 and 3-16) will be helpful.

|