4. Mold Design

4. 1 Sprue Design

|

Unsuitable sprue shape is a surprisingly frequent cause of problems during molding.

The following sprue shape is recommended to prevent problems.

(1) The sprue should be as short as possible, and have a sufficient gradient.

(2) Polish it thoroughly, with the direction of polishing the same as the direction of flow.

(3) Radius the sprue and runner corners.

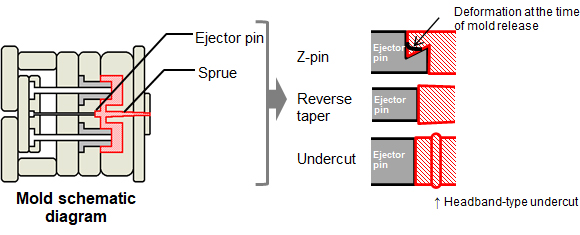

Further, generally, a Z-pin is used so that sprue ejection will be complete. However, in the case of a high-temperature mold, the low elasticity may cause the undercut to be deformed, making sprue ejection impossible. (Figure 4-1) In such cases, a reverse taper or headband-type undercut is effective.

|

|

|

|

Figure 4-1. Sprue Design Example

|

4. 2 Runner Design

|

RENATUS® PET has a high melting temperature, so we recommend designing runners such that there is as little cooling of molten resin as possible, and low pressure loss.

Runner shapes with round cross-sections are the best, but they have the disadvantage of requiring digging into fixed and moving molds. Accordingly, trapezoidal runners are frequently used, but as a standard, we recommend the following dimensions.

Upper base length = (0.6 to 0.7) x (Lower base length)

Depth ≅ Upper base length

Further, be sure to put cold slug wells at the runner intersection and end points.

RENATUS® PET can also be molded with hot runners, but attention must be given to the following points.

(1) In the case of grades containing glass fiber, consider materials to prevent hot chip and manifold wear.

(2) Give attention to ensuring that no resin remains in the manifold or hot chip (particularly with a flame-retardant grade).

For other matters, there should be no problem if you pay attention to the general points of attention for hot runner design.

|

4. 3 Gate Design

|

With RENATUS® PET, side gates, pin gates, tunnel gates, and other types of gate in general use can be used without any problem. However, a large gate is preferable, as a small gate would decrease cavity pressure. It is easier to have a good surface appearance and to suppress warpage deformation.

The following points must be taken into consideration when designing gates.

(1) Gate type: Make the decision in light of molded article quality, productivity, and automation, etc.

(2) Gate position and number of gates: These affect deformation, molded article strength (weld strength in particular in the case of compound grades), external appearance, etc. In particular, gate position and number of gates can be used as countermeasures against deformation.

(3) Gate size: As a rule, place gates with a thickness that is about 60% to 70% of the molded article thickness.

|

4. 4 Gas Vent

|

With RENATUS® PET, gas burns will occur if gas vents are designed poorly, causing the molded article to turn black or have gas fogging on the surface, resulting in insufficient surface gloss or other appearance-related problems.

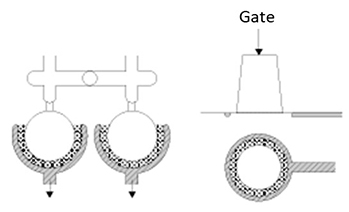

High-speed injection is often used to improve surface gloss, but sufficient attention must be given to gas vents. If the structure causes gas to be expelled from the parting line, it would be effective to have it extracted from the entire surface of the circumference of the molded article, as shown in Figure 4-2. Vent depth should be 2/100 mm or less.

|

|

|

|

Figure 4-2. Gas Vent Example

|

4. 5 Draft

|

The ejection performance of RENATUS® PET is the same as that of other resins, but we recommend the use of a large taper as much as possible.

If the set mold temperature is high (130°C to 150°C), elasticity will be low, and ejection may cause deformation, so we recommend using a taper of at least 1° for the draft.

In addition, it is necessary to give sufficient consideration to the knockout method and to knock pin location and quantity, etc., in order to achieve good ejection.

|

4. 6 Mold Temperature Regulation

|

Mold temperature significantly affects the molding cycle and molded article quality, etc.

RENATUS® PET is a crystalline resin, and its properties differ according to the degree of crystallization of the molded articles. To fully utilize the excellent properties (durability in particular), it is necessary to crystallize the molded article sufficiently. We recommend molding using a high-temperature mold.

Molding can be done with mold temperatures that are lower than the recommended temperature, changes to dimensions, deformation, surface roughness, etc., may occur due to insufficient crystallization, so be sure to give sufficient attention to molded article performance and moldability.

The following points must be considered when designing high-temperature mold temperature regulation.

(1) Selection of temperature regulation using a heater, or the oil or pressurized hot water, etc., circulation method

(2) Key points of the heater method

a) Place a heater to eliminate temperature fluctuation as much as possible.

b) Place temperature detection equipment and control equipment independently on the moving side and the stationary side to control mold temperature.

(3) Key points of the oil or pressurized hot water circulation method

a) Ensure the prescribed heat transfer area.

b) Place the cooling holes as close to the cavity as possible. (For mold surface temperature distribution)

c) Consideration of core cooling. (Affects the molding cycle, deformation, and ejection performance, etc.)

(4) Insert a thermal insulation plate between the mold installation plate and the molding machine installation plate.

|

4. 7 Mold Materials

|

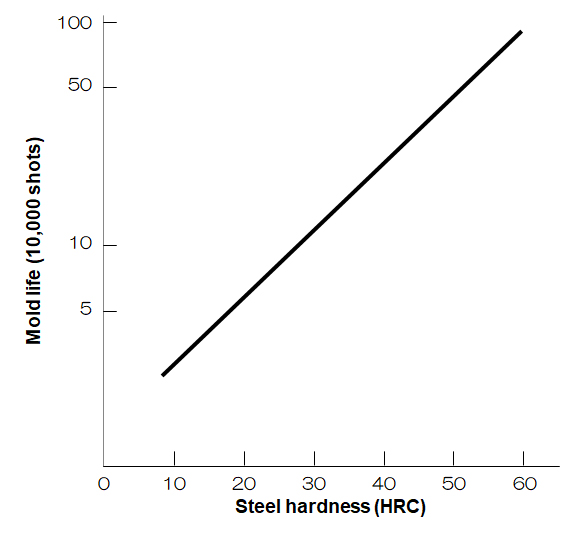

The life of the mold due to wear is affected more by hardness than by the mold materials. Figure 4-3 shows guidelines for the relationship between steel material hardness and mold life. In the case of the UL V-0 brand, it is necessary to take into consideration not only wear, but also corrosion, so we recommend using the items marked by A or B in Table 4-1.

|

|

|

|

Figure 4-3 Steel Material Hardness and Mold Life (Guidelines)

|

| Table 4-1 The Corrosion-resistance of Each Type of Steel Mold Material (Visual Observation) |

| Steel grade |

Code |

Hardness

HRC |

RENATUS®

(V-0) |

PBT

(V-0) |

| Stainless steel (ferritic) |

SUS410 |

42.5 |

C |

B |

| UL die steel |

UL-B |

35.0 |

B |

B |

| UL die steel |

UL-C |

35.2 |

B |

B |

| Deposition-hardened steel |

PSL |

45.0 |

B |

B |

| Maraging steel |

YAG-300 |

54.8 |

B |

B |

| High-speed steel |

SKH 2 |

66.4 |

D |

D |

| High-speed steel |

SKH 51 |

65.2 |

E |

E |

| Alloy tool steel |

SKD 11 |

61.8 |

B |

C |

| Alloy tool steel |

SKD 61 |

49.3 |

D |

E |

| High-Si stainless steel |

HSiS |

42.0 |

A |

A |

| Structural carbon steel for machinery |

S55C |

28.0 |

E |

E |

|

|

Note) A: Excellent, B: Very Good, C: Good, D: Average, E: Poor

Exposure conditions: RENATUS® PET 280°C x 5 hr, PBT 255°C x 5 hr

|

|