Home > Technical Support > Molding Technology > Molding Technology for RENATUS(R) PET

Molding Processability

3. Molding Processability

3. 1 Flowability

|

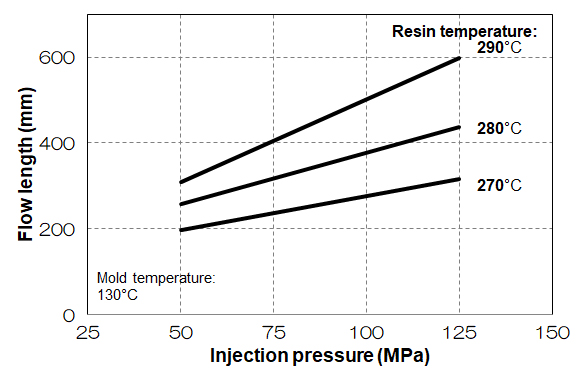

RENATUS® PET is a molding material that has excellent flowability. One method of evaluating flowability is the flow length measurement test that uses an injection molding machine. Figure 3-1 shows an example of the dependence of the C3030FA bar flow length on the molding conditions.

|

|

|

|

Figure 3-1. The Relationship between the C3030FA Bar Flow Length (thickness: 2 mm) and Molding Conditions (resin temperature and injection pressure)

|

3. 2 Mold Mold Shrinkage

|

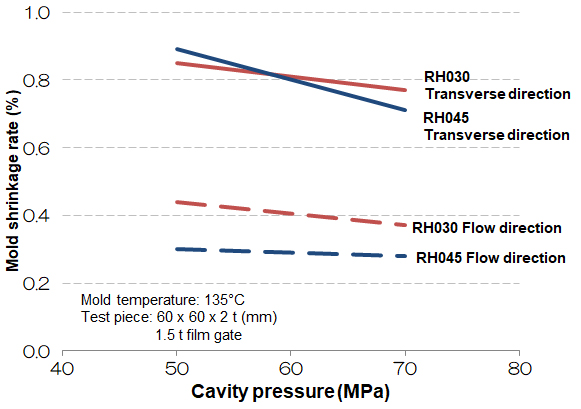

RENATUS® PET is a crystalline plastic, and in the case of grades reinforced with glass fiber, the flow inside the cavity causes the glass fibers to be oriented in the direction of flow. As a result, with the direction of flow, the mold shrinkage rate is lower than the direction at a right angle to the flow, and anisotropy is seen in the shrinkage rate, so deformation of molded articles becomes a problem. The shape of the molded articles and design of the gate are important as countermeasures against deformation. Further, in general, the mold shrinkage rate is affected by molding conditions. Figure 3-2 shows an example of mold shrinkage rate.

|

|

|

|

Figure 3-2. The Dependence of the Mold Shrinkage Rate of RENATUS® PET on Cavity Pressure

|

3. 3 Recycling

|

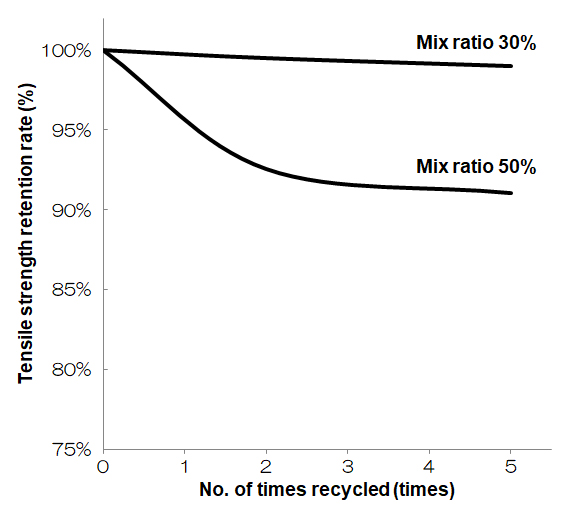

Recycled materials are affected by their thermal history more than virgin materials, so their molecular weight is low, and mixing in a large amount of such materials is a cause of decreased strength. In particular,

be sure to avoid the reuse of molded articles and runners that have undergone hydrolysis or thermal decomposition.

|

|

|

|

Figure 3-3. Recycled Material Mix Ratio and Tensile Strength Retention Rate (CN9030)

|

|

Table 3-1. Composition of Mixed Items When 30% Recycled Items are Mixed with New Pellets

|

No. of times

recycling repeated |

New pellet |

Items

recycled

2 times |

Items

recycled

2 times |

Items

recycled

3 times |

Items

recycled

4 times |

Items

recycled

5 times |

| (%) |

(%) |

(%) |

(%) |

(%) |

(%) |

| 1 time |

70 |

30 |

|

|

|

|

| 2 times |

70 |

21 |

9 |

|

|

|

| 3 times |

70 |

21 |

6 |

3 |

|

|

| 4 times |

70 |

21 |

6 |

2 |

0.8 |

|

| 5 times |

70 |

21 |

6 |

2 |

0.6 |

0.2 |

|

|