2. Selection of Molding Conditions

2. 1 Standard Molding Conditions

|

The standard molding conditions of RENATUS® PET are as indicated in Table 2-1.

|

| Table 2-1 |

| Flammability |

Example of applicable grade |

Resin

temperature*1 |

Mold temperature |

Predrying*2 |

| (°C) |

(°C) |

(°C×hr) |

| Slow burning |

Standard: RH030, RH045, B3030FA |

270-290 |

120-140 |

130-140 x 5

or more

(Maximum:

24 hours) |

| Easy crystallization: B9030 |

100-140 |

Flame

retardancy |

Standard: BN3030SD, CN3030SD |

265-280 |

120-140 |

| Easy crystallization: BN9015, BN9030 |

100-140 |

|

|

*1: Indicates the temperature of the molten resin, not the set temperature of the molding machine cylinder.

*2: Use of a dehumidifying dryer is recommended. In addition, use of a hopper dryer is recommended to prevent moisture absorption during molding.

|

Other conditions

| ·Holding pressure | : 60 MPa to 100 MPa |

| ·Cooling time | : Plasticization time + α or the time during which ejection is possible |

| ·Screw rotation speed | : 100 rpm to 150 rpm |

|

2. 2 Predrying

|

RENATUS® PET is a thermoplastic polyester, so molding while water has been absorbed will cause hydrolysis, making the molded articles vulnerable. Accordingly, predrying of pellets is extremely important, and requires careful attention.

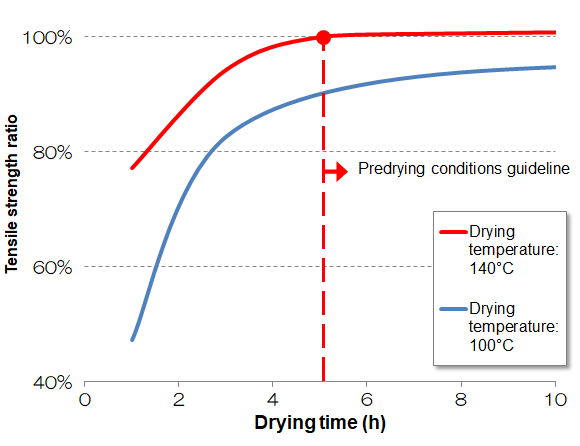

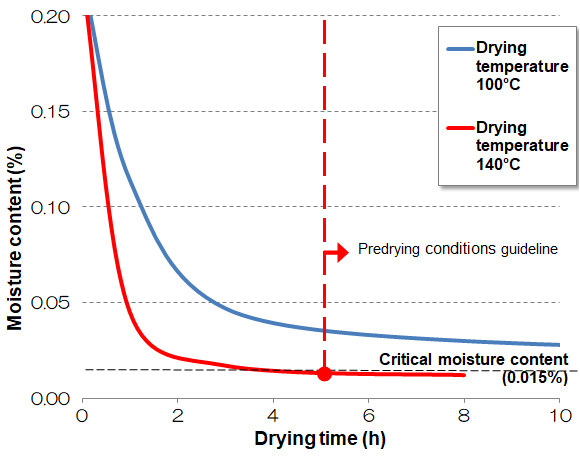

The relationship between drying time at 140°C and changes in physical properties is shown in Figure 2-1. At 140°C, drying for at least five hours is required. However, at high temperatures, such as 160°C, problems of discoloration occur more easily, and at 100°C or lower, it will be impossible to lower the amount of moisture in pellets to the target of approximately 0.015% or less, even if drying is conducted for an extended period of time. (Figure 2-2) In light of these facts, use 130°C to 140°C for five hours or more as a guideline for predrying conditions. If pellets are left at room temperature after predrying, they will absorb moisture, so be sure to keep them heated to prevent absorption of moisture.

Shelf-top circulation dryers and hopper dryers are used as the drying method, but in either case, it is necessary to adjust the temperature of the hot air and the amount of air flow, etc., so that pellets will be dried uniformly under the conditions given above. In the case of a hopper dryer in particular, it is important to check that the pellet temperature is as indicated above, and not the set temperature, in order to prevent a short path from being created. Use of a dehumidifying dryer is recommended for more effective drying.

|

|

|

|

Figure 2-1. The Relationship between Drying Time and Physical Properties (RENATUS® PET C3030FA)

|

|

|

|

Figure 2-2. Drying Curve (RENATUS® PET C3030FA)

|

2. 3 Resin Temperature

|

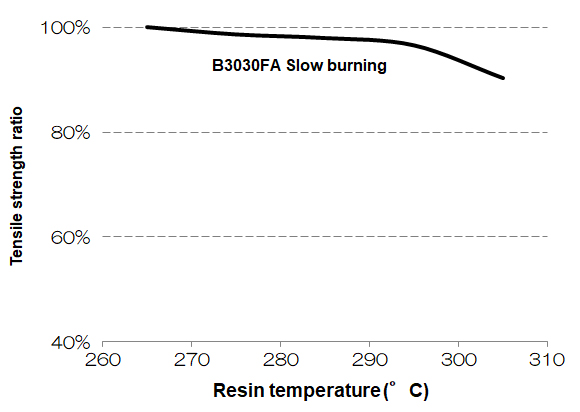

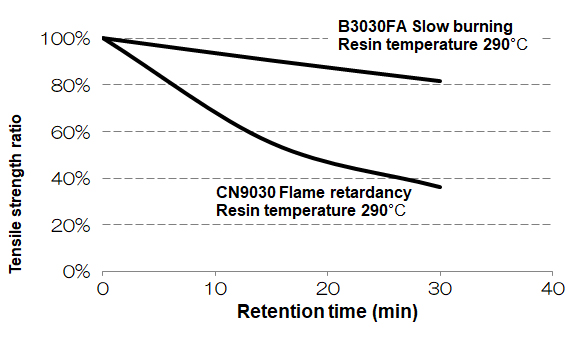

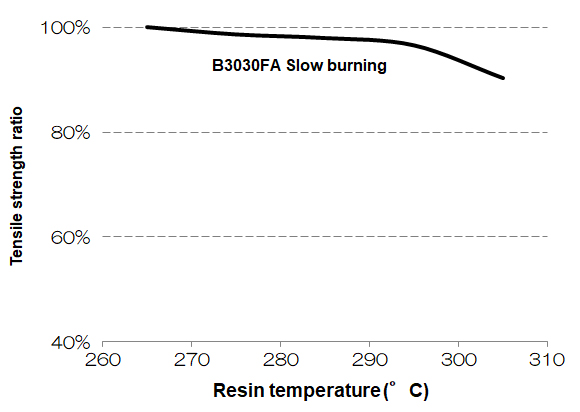

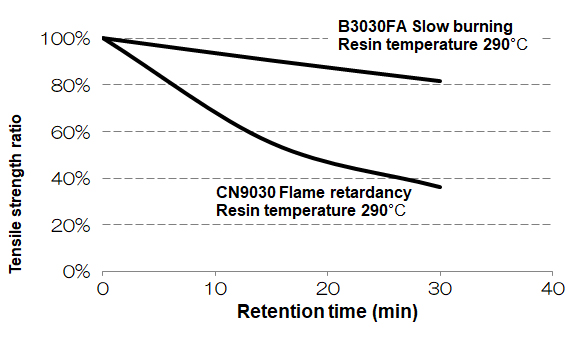

If the resin temperature is too high or the residence time in the cylinder is too long, during the molding process, thermal decomposition will occur, and strength will be reduced. (Figure 2-3, Figure 2-4) Accordingly, do not set the cylinder temperature too high.

In addition, set shorter molding cycles to prevent the residence time in cylinders from becoming too long, and select molding machines that have a capacity that is well-balanced with shot weight.

|

|

|

Figure 2-3. The Relationship between Resin Temperature and Tensile Strength

|

|

|

Figure 2-4. The Relationship between Residence Time in Cylinders and Tensile Strength

|

2. 4 Mold Temperature, Injection Speed, Molding Cycle

|

(1) Mold temperature

With RENATUS® PET, a higher mold temperature results in better surface gloss, dimensional stability, and degree of crystallization, but deformation increases. A low mold temperature is sometimes used as a countermeasure against deformation, but in this case, the use of high temperatures and annealing may cause deformation to increase, so the matter must be examined in advance. Ejection performance worsens in some cases, so be sure that the mold temperature is not increased too much.

(2) Injection speed

With RENATUS® PET, increasing the injection speed makes it possible to create molded articles with good surface gloss. However, because higher injection speeds make it easier for gas burns to occur, it is necessary to give the matter sufficient consideration when designing gas vents.

(3) Molding cycle

When molding RENATUS® PET, set the gate seal time with the injection timer (injection/dwell time) as a countermeasure against sink marks and deformation, and to reduce variance of dimensions.

|

|