Home > Products > DURANEX(R) PBT

Electrification of Cars Brings Changes to Material Design

| Electrification of Cars Brings Changes to Material Design: Focusing on Materials for PCUs |

|---|

| 1. Introduction |

The automotive industry is said to undergo a major transformation once every 100 years. Sure enough, the industry is now undergoing major changes, and CASE (Connected, Autonomous, Shared, Electric) is becoming a keyword. One of these changes is electrification, as environmental problems are accelerating a shift away from the use of fossil fuels, from internal combustion engines (ICEs) to electric vehicles (HEVs, PHEVs, EVs, and FCVs) mainly in Europe and China. The UK and France will ban the sale of ICEs starting in 2040, while Norway, the Netherlands, India, and China are also announcing policies to sell only EVs and HEVs. Electrification is here, and as it progresses Polyplastics is also developing resin products that can accommodate electric vehicles. |

| 2. Auto parts that electrification will change |

ICEs use fuel to drive an engine, but EVs use electricity from a battery to drive a motor. Along with large capacity batteries and motors to be driven, EVs also require charging guns and inlets to recharge the battery, and power control units (PCUs) to control the output of the motor. These parts operate at much higher voltages and electrical currents than previous cars, and these need to be controlled. |

|

|---|

| 3. Resins needed for PCUs |

Since PCUs drive motors, they have functions to either convert direct voltage supplied from the battery into three-phase AC voltage, or to convert AC voltage produced by a generator into direct voltage in order to charge the battery. Resin is used as an insulating part. It is used for reactors, inverter cases, current sensors, DC-DC converters, and more. Since PCUs carry high voltages and high currents, they require resins with high insulating properties in a usage environment. Due to size and weight reduction advancements in recent years, resins should now also be heat shock and solder heat resistant. Auto parts are used in very harsh environments (-40 to 150℃, up to 95% relative humidity), so resins need to have resistance to those environments. Loss of insulation properties due to water absorption is a point of concern for high voltage parts such as PCUs. Polyplastics products DURANEX® PBT and DURAFIDE® PPS have low water absorption rates, and possess the characteristic of maintaining insulation properties even in the harsh environments of cars, so they are used in many high voltage parts. Below we will share an example of Polyplastics products with a proven usage track record. |

| 3-1. DURANEX® PBT CG7030 with outstanding tracking-resistance properties | |

Here we will introduce DURANEX CG7030 as an example of usage in high voltage auto parts. This material has high tracking properties※ (CTI: 600V), and in design it can help ensure high reliability for high voltage parts that do not gain enough creepage distance. To offer materials with the properties required, we also sell the following grades imparted with a variety of different attributes. |

|

|---|

※About tracking function |

|

|---|

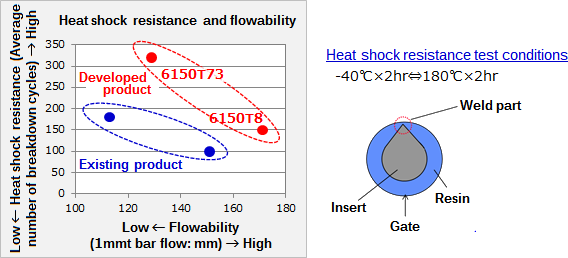

| 3-2. DURAFIDE® PPS 6150T73 with outstanding heat shock resistance | |

To satisfy demand in recent years for size and weight reduction of parts, methods that integrally mold resins with metals (insert molding) have become mainstream. Differences between the linear expansion coefficients of the metal and the resin can cause the resin to crack when temperature changes, so resin needs to have high heat shock resistance to prevent that from happening. At the same time, high dimensional accuracy is also required in order to maintain the position of metal parts. To meet market needs such as these, Polyplastics developed DURAFIDE 6150T73. This grade is a PPS resin with high heat and chemical resistance, which has been imparted with outstanding heat shock resistance functionality and workability, as well as high dimensional accuracy. Previous technologies had the problem that heat shock resistance would decline when moldability (flowability) is increased. To address this, we have created a new grade that combines high moldability with heat shock resistance by optimizing the PPS base polymer and each of the different filling materials and additives, and modifying the compound technologies. It is now being chosen more and more for parts geared towards the electrification of cars. |

| ◯The mechanism of heat shock cracking |

|

|---|

| ◯Heat shock resistance functionality improvement |

|

|---|

4. Developing materials for the future |

Resin is used for insulation applications in PCUs, but the casing itself is metal. Future trends may call for this casing to be made of resin instead. Better power consumption (lighter weight) and productivity are cited as benefits of shifting to resin casings. However, there is also a big obstacle in the way. Typically, strength and dimensional accuracy (changes) are issues when shifting toward resin-made products, but electrification parts such as PCUs require resin that is more metal-like, so the issues also include electromagnetic shielding and thermal conductivity. Polyplastics is developing materials that address these issues in electrification parts. |

| ◯Requirements for resin in next-generation cars |

|

|---|

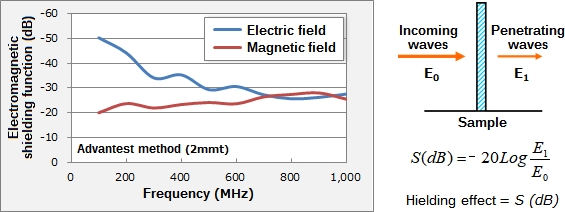

4-1. Development of electrically conductive grades |

Electrification in cars requires engineering to counteract electric noise (※EMC) in each of the parts. Big problems can occur when electric noise causes malfunctions in the electronic control units (ECUs) of cars. Metals have strong shielding properties against this electric noise (electromagnetic waves). On the other hand, standard resins have hardly any shielding properties at all, so switching to resins as-is would be dangerous in this case. We are currently developing materials that collaterally possess electromagnetic shielding properties while exploring the needs of the market. |

| ◯Shielding properties of materials in development |

|

|---|

※EMC (electromagnetic compatibility) means balancing EMI (electromagnetic interference) with EMS (electromagnetic susceptibility). |

5. Conclusion |

Here, we mainly introduced materials geared toward PCUs. In the current market, development is ongoing on a variety of parts geared towards electrification, including for motors and batteries. At another time, we plan to share the trends in materials for parts other than those made for PCUs. As a specialized manufacturer of engineering plastics, we are pushing forward with the development of materials that meet market needs. |

Technical data sheet is available online: |

◆6150T73 |

For inquiries about our technologies |

◆Polyplastics Group Representative |

| ◆WEB Inquiry |

19th March 2019 |