Home > Products > DURANEX(R) PBT

Introducing Materials and Technologies for ADAS Parts - Sensor Edition

Materials and Technologies for ADAS Parts - Sensor Edition |

|---|

| 1. Introduction |

In the previous edition, we explained that more parts are being made for Advanced Driver-Assistance Systems (ADAS) to enable autonomous driving. We also introduced Polyplastics products such as DURANEX® PBT in particular, which have the resin properties needed for increasingly common by-wire systems and the electric actuator that powers driving operation. In this Sensor Edition, we will focus on radar and camera brackets as shown in Illustration 1 and explain the characteristics and materials requirements for the related parts, along with related technological trends. |

|

Illustration 1: Autonomous driving-related part applications for engineering plastics and super engineering plastics |

|---|

| 2. Materials for radar parts |

| 2-1. Materials that require radio wave transmissibility |

Radar devices detect returning radio waves that have irradiated off of objects to determine the distance to the object and its direction. Cars can be equipped with long-range radar (expressed as LRR, forward direction, 77 GHz millimeter-wave) that detects over relatively long distances, and short-range radar (expressed as SRR, rear direction, 24 GHz quasi-millimeter wave) which detects over short distances. LRR serves the function of monitoring moving vehicles ahead, while SRR is used in systems that inform the driver about moving vehicles behind which could enter the driver's blind spots, and about vehicles approaching from the side and behind when moving in reverse. Radar is comprised of an antenna board and the housing that encloses it. The housing serves dual purposes as both a cover or case to protect the radar apparatus, and as a lens through which the radio waves pass. For this reason it is frequently called a radome. Subsequently, radio wave transmissibility in the usage frequency band is an important parameter for the resin used in the radome. From that standpoint, materials need both low dielectric constant and stable radio wave transmissibility. Water absorption rate is also considered to be an important parameter since the electrical properties can typically change due to water absorption. The market has been employing SPS and PEI for dielectric properties, and PPS for low water absorption and chemical resistance. As radar has turned into a commodity, many manufacturers have tried to lower costs by combining PBT with their production methods, and they are producing many different models. |

|

Illustration 2: Required characteristics of radar housing |

|---|

| 2-2. Changes in radio wave transmissibility due to moisture absorption |

In the previous paragraph we expressed the importance of radio wave transmissibility due to dielectric properties in the assessment of radar that utilizes a dielectric. Illustration 3 shows general knowledge of the Free-space method (S-parameter method), a well-known assessment method for radio wave transmissibility. Illustration 4 has indicated the change in radio wave transmissibility S21 before and after moisture absorption treatment. Illustration 4 shows that radio wave transmissibility parameter S21 decreases from its state before moisture absorption treatment indicated by the solid line, to its state after moisture absorption treatment indicated by the dotted line. In other words, radio wave transmissibility worsens. Furthermore, water absorption has little effect on DURAFIDE® PPS 1140A6, while we can also see that it has a much larger effect on DURANEX 330HR. Because of this, we expect that PBT will need to have enhanced low-dielectric properties and low water absorbance in the future. Polyplastics will also continue studying PBT materials development. |

| ● About electromagnetic wave shields (general knowledge) |

|

| Feldtkeller equation: Expansion from |S11|2 + |S21|2 = 1 |

Illustration 3: Explanation of S-parameter method |

|---|

|

|

||||||||||||

|

|||||||||||||

Illustration 4: Comparison of radio wave transmissibility before |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2-3. Electromagnetic wave shielding properties of electrically conductive grades |

Radar can mistakenly detect unintended radio waves that are reflected on the inside of the bumper, and onto the surface of the road or in other unintended directions. Unnecessary reflected waves must be shielded in order to prevent this, and we see cases in the market where this is addressed by installing electromagnetic wave shielding covers. As such, it seems likely that the functions of both the electromagnetic wave shielding cover and the radar bracket can be achieved uniformly by adding electromagnetic wave shielding properties to the radar bracket itself. Electromagnetic wave shielding typically has three mechanisms-reflection loss, absorption loss, and multiple reflection loss. However, since loss form multiple reflection is minimal, we will not be addressing it here. First is reflection loss, which can be caused by using an electric conductor. Here we will introduce the electromagnetic shielding properties of Polyplastics electrically conductive grades DURACON® POM CH-10 and EB-10, and DURANEX 7300E. The aforementioned Free-space method (S-parameter method) is used to measure electromagnetic shield properties. In Illustration 5, we showed the radio wave transmissibility parameter S21 of each grade at 77 GHz and compared them to the reflection coefficient parameter S11. Note that S21 is a negative value, and electrically conductive grade DURACON CH-10 has a very small radio wave transmissibility parameter S21 (dB). In the previous section 2-2, we showed that transmissibility increases as the value of S21 gets closer to zero. However, for electrically conductive grades, large negative value of S21 indicates low radio wave transmissibility, which in turn indicates superior electromagnetic wave shielding properties. Next, Illustration 6 indicates the energy loss rate of electromagnetic waves based on the Feldtkeller equation (|S11|2 + |S21|2 = 1) in Illustration 3. Setting total wave emission to one, we see the rate of absorption loss (Illustration 6, left) and reflection loss (Illustration 6, right). Looking at this together with Illustration 5, we can see that DURACON EB-10 and DURANEX 7300E have electromagnetic wave shielding properties inferior to CH-10. When we break down the factors of the shielding properties, we see that the rate of absorption loss (Illustration 6, left) is rising which tells us that the characteristics of the electromagnetic wave shielding properties differ by material. |

|

Illustration 5: Comparison of radio wave transmissibility at 77 GHz |

|---|

|

Illustration 6: Breakdown of electromagnetic shield property mechanism at 77 GHz using Free-space method (S-parameter method) |

|---|

Based on the above, using these materials in the radar bracket would likely help to prevent detection errors. Polyplastics is also conducting ongoing studies to develop PBT materials with stronger electromagnetic wave shielding properties. |

| 3. Matte technologies for car-mounted sensing camera brackets |

| 3-1. Materials for front-facing car-mounted sensing cameras |

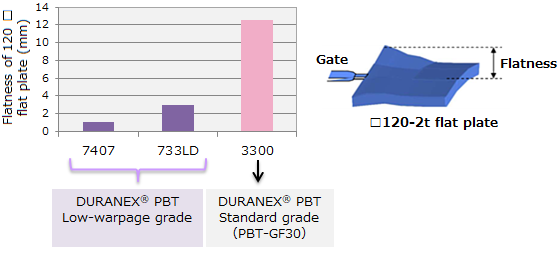

Front sensing cameras are bonded to the windshield on the reverse side of the rearview mirror through the mirror bracket. Since the bracket serves to constantly hold the camera in place, low-warpage and high-rigidity materials are generally preferred. Here we will introduce two Polyplastics grades that have low warpage, DURANEX 733LD and 7407. In Illustration 7, we compared the warpage deformation of DURANEX 733LD and 7407 on a flat plate. Compared to general-purpose glass fiber reinforced grade DURANEX 3300 we can see the warpage deformation of both grades is improved. However, as Table 1 indicates, if we look at flexural modulus as an index for rigidity, we see that both grades maintain their rigidity. |

|

Illustration 7: Comparison of low warpage of DURANEX® PBT 733LD and 7407 |

|---|

Table 1 : Mechanical properties of DURANEX® PBT |

| Parameter | Unit | Testing method | 3300 | 733LD | 7407 |

| Standard | Low warpage Hydrolysis resistant |

Ultra-low warpage | |||

| General properties | PBT-GF30 | PBT+SAN-GF30 | PBT+PC-(GF+GS)40 | ||

| Density | g/cm3 | ISO 1183 | 1.53 | 1.46 | 1.57 |

| Water absorption rate (23℃, immersed 24hrs, 1mmt) |

% | ISO 62 | 0.1 | 0.2 | 0.1 |

| Tensile strength | MPa | ISO 527-1,2 |

140 | 139 | 117 |

| Strain at break | % | ISO 527-1,2 | 2.2 | 2 | 2.5 |

| Flexural strength | MPa | ISO 178 | 220 | 180 | 180 |

| Flexural modulus | MPa | ISO 178 | 9,030 |

9,000 | 9,500 |

| Charpy impact strength (notched, 23℃) |

kJ/m2 | ISO 179/1eA | 10.5 | 7.6 | 8.8 |

| Deflection temperature under load (1.8MPa) |

℃ | ISO 75-1,2 | 213 | 195 | 200 |

| 3-2. Processing methods for front sensing camera brackets |

Front sensing camera brackets must not allow noise (scattered light) to enter the optical area. Typically, this is addressed by incorporating paints and non-woven fabrics into the hood part of the camera lens to reduce glossiness. However, the processes for these methods are considered to be cumbersome and costly. On the other hand, while matte by embossing is possible, this is considered to be problematic in terms of quality assurance. For these reasons, we will introduce matte technology by laser treatment as an alternative method. We considered the conditions for laser treatment according to the gloss levels (0.5 to 1.5) and blackness levels (L value 20 to 32) of products distributed in the market. Photo 1 shows the outer appearance of a produced sample (DURANEX 3300), and Photo 2 shows an illustration of laser treatment. We also listed the gloss level and blackness level (L value) of the produced sample in Table 2. As a result of the study, we found favorable gloss and blackness levels with laser treatment conditions C and D. Going forward, we plan to conduct research on long-term durability and explore different treatment conditions to reduce treatment time. |

|

|

||||||||||||||||

Photo 1: Laser-treated flat plate |

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||

| Photo 2: Illustration of laser irradiation (grid pattern) | |||||||||||||||||

| 4. Conclusion |

Here we have introduced trends in materials for radomes and radar brackets from among materials applications for parts used with ADAS sensors. We have also introduced laser treatment as a processing method for surface gloss level. As a manufacturer specialized in engineering plastics, Polyplastics will continue developing materials and production methods that are tailored to market needs. |

[Related information] • Introducing Materials and Technologies for ADAS Parts - Actuator Parts |

Technical data sheet is available online: |

|

|||||||||||||

For inquiries about our technologies |

◆Polyplastics Group Representative | |||||||||||||

| ◆WEB Inquiry |

< Reference > Frequency Assignment Plan, Radio Use Web Site of the Ministry of Internal Affairs and Communications |

12th January 2021 |