Home > Products > DURANEX(R) PBT

Introducing DURANEX(R) PBT 330LW

DURANEX® PBT 330LW |

|---|

| 1. Introduction |

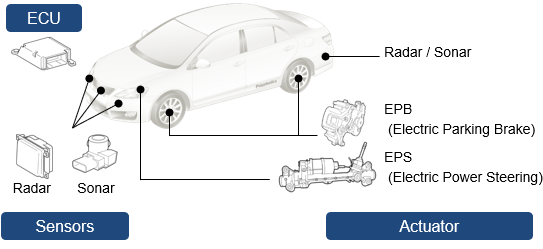

Polyplastics is launching 330LW, a new grade of DURANEX® PBT with superior laser weldability. 330LW is a grade with extremely high laser transmittance and low warpage, as well as superior laser weldability (Table 1). It is ideally suited for usage applications in laser welding for automotive sensors, ECUs, actuators, and various other items (Figure 1). We offer this new grade in two different colors, natural (EF2001) and black (LB3002). |

| Table 1 : Comparing properties of PBT grades (30% glass fiber reinforced) |

| 330LW Laser welding grade |

Competitor PBT Laser welding grade |

3300 Standard grade |

|

| Laser transmittance | +++ | ++ | + |

| Low warpage | +++ | + | + |

| +++ = Superior, ++ = Good, + = Normal |

|

Figure 1 : Anticipated usage applications |

|---|

| 2. High light transmissibility |

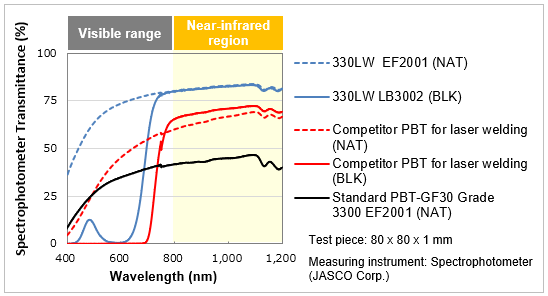

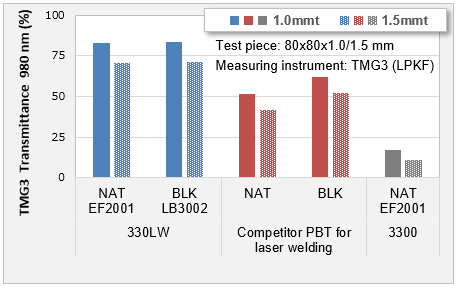

Figure 2 compares the light transmittance spectrums of 330LW EF2001 and LB3002 against other PBT grades in a spectrophotometer.*1 We can see that 330LW exhibits higher transmittance than other PBT grades in the 800-1,100 nm wavelength range (near-infrared region) used in laser welding. Figure 3 compares the thickness dependence of laser transmittance at specific wavelengths, using the TMG3 device*2 made by LPKF. As the thickness of the test piece increases, the transmittance of the laser decreases. We can see that even though 330LW has a thickness of 1.5 mm, it still has higher transmittance than other companies' 1.0 mm thickness PBT for laser welding.

*1 Wavelength 400-1,200 nm, 1 mmt flat plate *2 Wavelength 980 nm, 1.0/1.5 mmt flat plate |

|

Figure 2 : Comparing light transmittance spectrums |

|---|

|

Figure 3 : Comparing 980 nm laser transmittance (TMG3) of PBT flat plates |

|---|

| 3. Ease of laser welding |

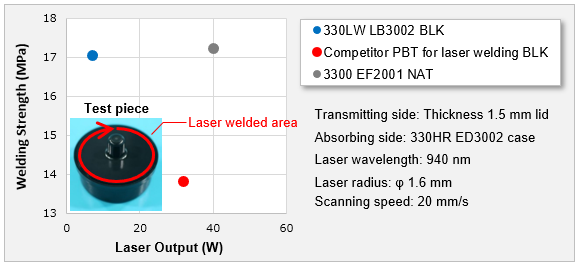

Figure 4 shows a comparative evaluation of laser welding strength after screening for suitable laser output conditions, using test pieces (1.5 mm thickness) of each different PBT. Compared to other PBT grades, we can see that the superior laser transmissibility of 330LW LB3002 results in adequate welding strength at low (energy-saving) laser output. Since it is easy to increase scanning speed, this shows the potential time reduction effects of 330LW in laser welding processes. |

|

Figure 4 : Comparing laser welding strength and suitable laser output |

|---|

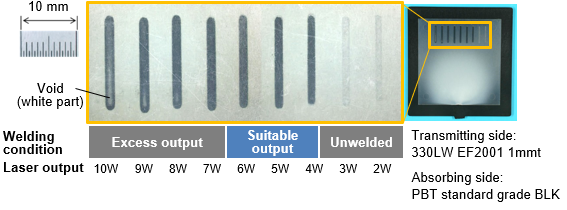

| 4. Visibility of laser welded area |

Figure 5 shows observations of outside appearance after a 1 mmt flat plate of 330LW EF2001 was placed atop a black PBT flat plate and laser welding was applied at various outputs from directly above. Since 330LW EF2001 shows higher transmittance than other PBT grades even in the visible range (Figure 2), the condition of its welded area is directly visible. Parts of the welded area that have been properly welded appear black, while voids and unwelded parts are white. Since the coloration differs, this can serve as a reference when verifying the quality of laser welded areas. |

|

Figure 5 : Visibility of welded area of DURANEX® PBT 330LW EF2001 |

|---|

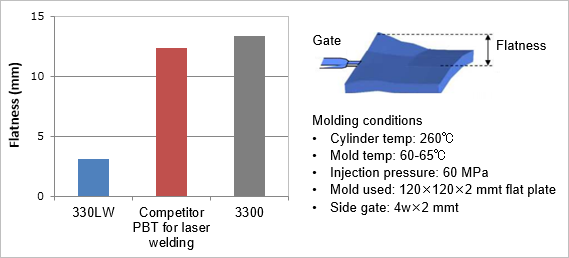

| 5. Excellent low warpage |

Figure 6 compares the flatness of 330LW and existing PBT grades. Compared to the existing PBT grades, we can see that 330LW has superior low warpage and lower values for flatness. If molded products bend, clearance arises in the weld area which makes welding harder. However, if products are made with 330LW which has superior low warpage, occurrence of clearance in the weld area is inhibited and laser weldability improves. |

|

Figure 6 : Comparing plate flatness with DURANEX® PBT 330LW |

|---|

| 6. In conclusion |

330LW is a new grade that drastically improves the laser transmittance and low warpage properties that are key to satisfying market needs in laser welding. At Polyplastics, we will continue developing grades tailored to market needs and usage applications for our customers. |

Technical data sheet is available online: |

|

|

For inquiries about our technologies |

◆Polyplastics Group Representative | |

| ◆WEB Inquiry |

27th April 2022 |