Home > Technical Support > Molding Technology > Molding Technology for DURANEX(R) PBT

Cylinder Temperature

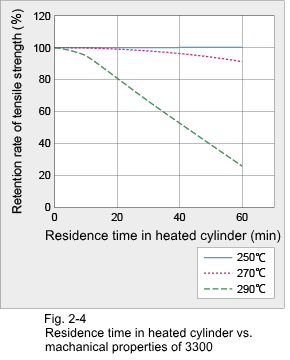

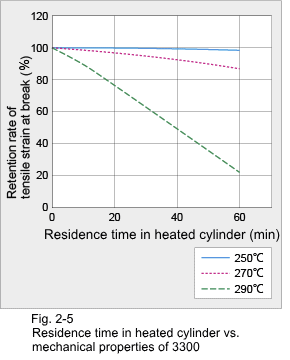

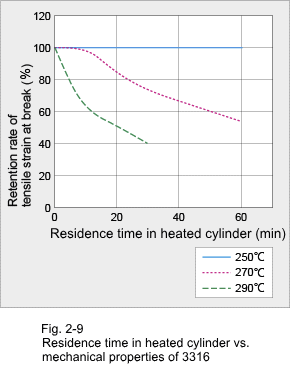

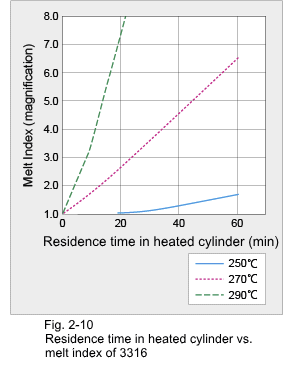

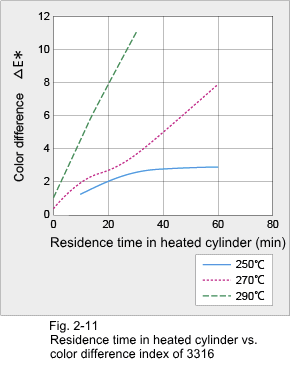

2.3 Cylinder Temperature Because the melting point of DURANEX® PBT is around 224°C,the appropriate resin temperature is from 250°C to 270°C. If the temperature exceeds 280°C, decomposition begins; therefore, a temperature around 270°C should be considered as the upper limit. The effects of cylinder temperatures and residence time in the heated cylinder on mechanical properties of DURANEX 3300 are shown in section (a) Figs. 2-4 through 2-7, and DURANEX 3316 in section (b) Figs. 2-8 through 2-11. It is a matter of opinion what value should be regarded as the limit but in Table 2-1, the longest allowable residence times are estimated from such points as the melt index rises to 2 times of its initial value and color difference more than 2.5 of their original levels. (a) Residence Time in Heated Cylinder vs. Various Properties

(b) Residence Time in Heated Cylinder vs. Various Properties

Table 2-1 Resin Temperature vs. Allowable Residence Time of DURANEX® PBT

|

|||||||||||||||||||||||||||||||