Typical molds and molding methods

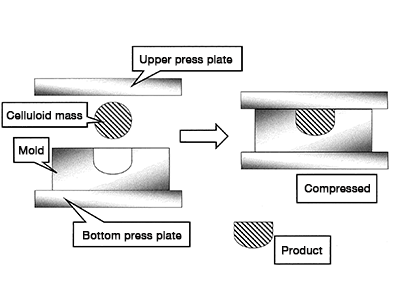

Compression molding

A characteristic of celluloid is its flexibility, which makes forcible extraction possible after molding. Compression molding is a method by which a top press plate is used to press a mass of softened celluloid into the mold.

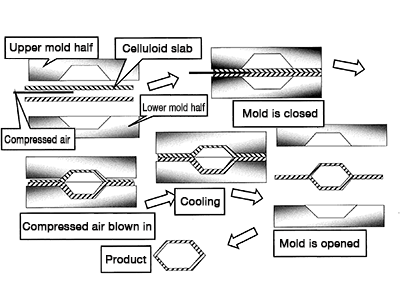

Blow molding

Blow molding

Blow molding is done with two celluloid slabs. The mold is heated while the mold is in an open condition, the slabs are placed within the mold cavity, and the mold is closed. A thin pipe is inserted between the celluloid slabs and compressed air is blown in to inflate the slabs so that they take the shape of the mold cavity, then the part produced is cooled.