Home > Technical Support > Molding Technology > Molding Technology for TOPAS(R) COC

Molding conditions

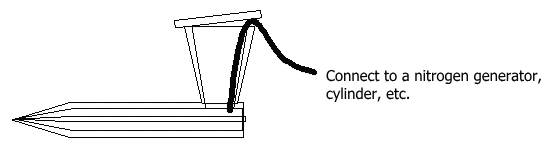

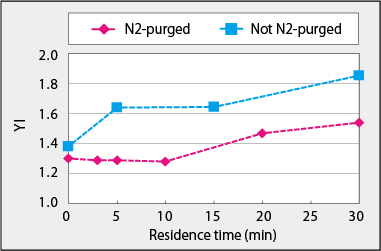

4. Molding conditions 4.8 Nitrogen purge of hopper Nitrogen purge or evacuation of the hopper is strongly recommended. Removal of oxygen from the place where the resin starts melting can restrain carbide formation on the screw and cylinder, and also can restrain discoloration especially when cylinder temperature is relatively high. For nitrogen introduction into the hopper, you should, in principle, connect parts including a nitrogen input port, which should be purchased from your molding machine manufacturer, but as far as testing is concerned, you may input nitrogen by inserting a tube into the cylinder inlet as shown in Fig. 4-3. Seal up the gap between the tube and hopper lid with tape, etc., to some extent. As for nitrogen to be input, residual oxygen concentration should be approximately 0.1% or less, and flow rate, which cannot be determined categorically because airflow in the hopper loader, hopper dryer, etc., should be taken into consideration, can be several nano-liters per minute if airflow in the hopper is low and molding is stable. Fig. 4-4 shows an example of the effects of whether the hopper is nitrogen-purged or not. In normal molding, there is little difference between nitrogen-purging and not nitrogen-purging, but when subjected to residence, the degree of discoloration is clearly restrained low by nitrogen introduction.

Fig. 4-3 Effects of whether hopper is nitrogen-purged or not (example)

Fig. 4-4 Residence time and YI of 6015S-04

|